Warning! Don’t accept heavy lifting and bad working environment

Working in the building industry is hard work. Your day start early in the morning and you often must do heavy lifting and carry work material over long distances. This creates a bad working environment and takes the joy out of your work. In this article we focus on heavy lifting and work environment and introduce some solutions on how to make it better.

Good Working Environment

The Danish Working Environment Authority have made some guidelines about how much employees, in the industry can lift, carry, and push to ensure a good working environment where nobody get hurt. Your employer has a duty to follow the rules and make sure the right lifting tools are there to help you carry out your work.

Rules about heavy lifting

Heavy lifting may cause pain and problems in muscles, and joints, particularly in the back. Pushing or pulling can cause the same problems. Sudden or heavy strain can also cause acute injury.

Minors under 18 years old can only lift up to 12 kg and pull or push up to 240 kg.

A person over 18 years old can, if the lift conditions are in order, lift up to 25 kg, if the lift is performed at arm’s length and under optimal conditions.

These are the rules but sometimes you are in a hurry or the lifting tools are not there to help you and then you end up carry e.g. heavy cobber cables all over the building site. This can result in back injuries and sick days. A back injury following long term work in an incorrect working position is a work-related ailment and must be reported to the Working Environment Authority. So, measures must be taken to ensure a good working environment.

To get more information please refer to the Manual – Building and Construction – Working Environment.

The manual is a guide to good practice concerning the working environment in the building and construction sector. It provides guidance on how to comply with the regulations of the Working Environment Act.

How to reduce weight when working with cables

Traditionally, the cable used for temporary power on construction sites have been H07RN-F copper cables. They are heavy to carry around and might, over time, contribute to back injuries due to the heavy lifting and poor working positions. But Alukaflex® aluminum cables can help with that. They offer a weight reduction up to 40% compared to copper cables. Depending on length, and conductor size. The flexible Alukaflex® cable uses fine stranded aluminum conductors. This provides an equally flexible cable as similar copper cables, and they are protected by premium rubber or PUR materials that can withstand a 90°C conductor temperature which allows the same current to be run as on a H07RN-F copper cable. But they weigh less due to the aluminum conductor .

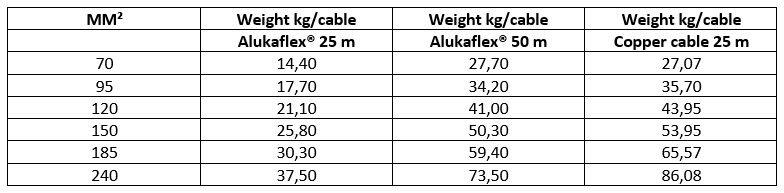

When comparing the weight of aluminum cables to copper cables the advantages is clear. You will get twice the length of cable in aluminum at the same weight.

See examples.

Significant lower price on aluminum cables

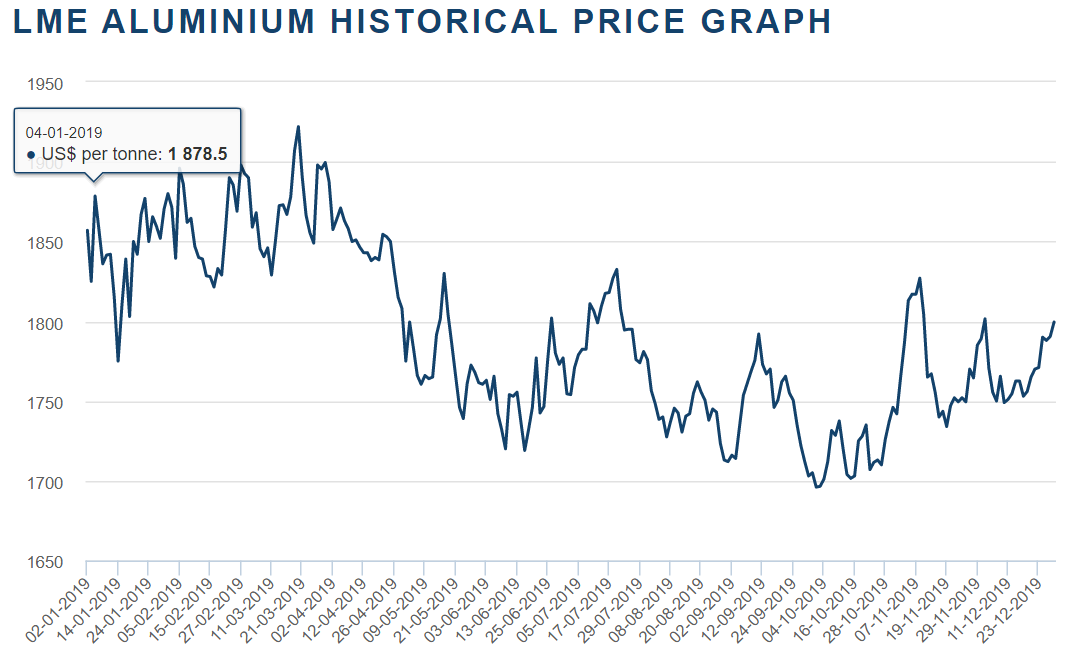

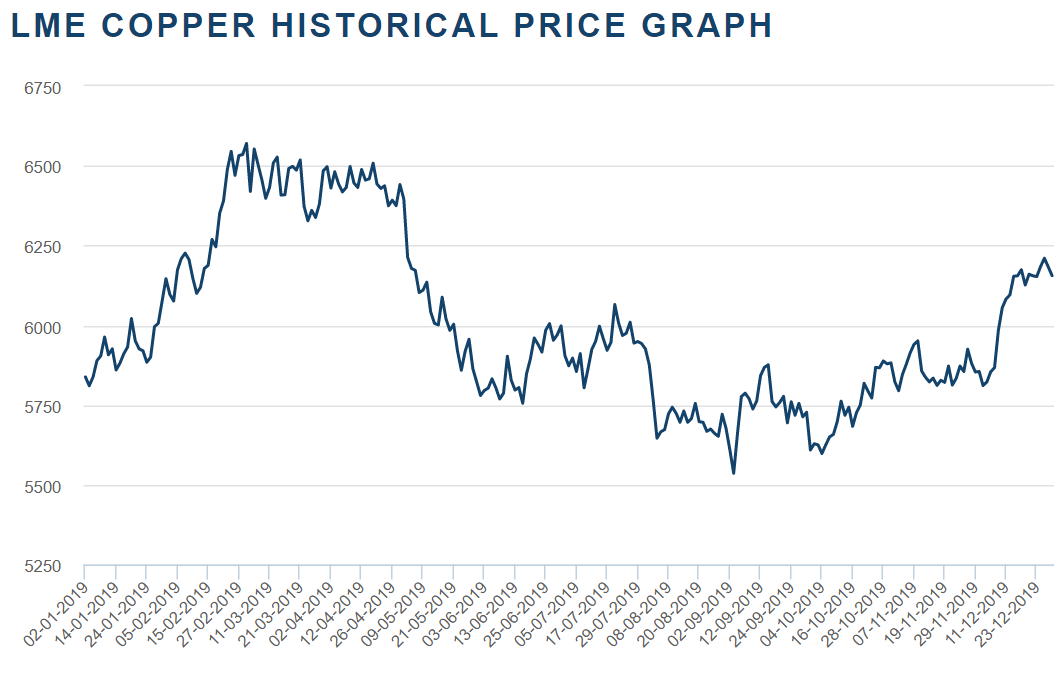

Even though Alukaflex® aluminum cables are made with high quality materials the price is surprisingly low. Below you can see the price trend for copper vs. aluminum in 2019. It clearly shows that although the copper price fell on the world’s metal exchanges, it is still considerably higher than on aluminum. This affects cable manufacturers’ purchase prices, which ultimately results in fluctuating prices for the final cable. The aluminum cables are more price stable, so using Alukaflex® aluminum cables can bring big cost savings in a construction project or for other projects.

Low scrap value

Another benefit by using Alukaflex® aluminum cables, besides low risk of heavy lifting and bad working environment, is the low scrap value. With a relatively high copper scrap price of approx. 4,2 – 4,6 € kg. It is attractive for the cable thieves to ransack construction sites, as it is almost impossible to secure the copper cables on site. By replacing the copper cables with new Alukaflex® aluminum cables you will avoid cable thieves because the low scrap value makes them less interesting for the thieves to steal. And if they try, they will only do it once. Alukaflex® is supplied with a very recognizable white stripe (black on the yellow PUR cable), which makes it easy to see the difference between them and copper cables.

Additional benefits with Alukaflex® aluminum cables

- Very easy to handle due to the lower weight

- Excellent flexibility makes it easy to bend and coil

- High conductivity can match copper performance

- Exceptional material properties

- Ozon resistant (rubber)

- UV and oil resistant

- Halogen free (PUR cable only)

- Flame retardant

- Flexible in low temperature

Contact us

We hope you found answers to how Alukaflex® aluminum cables can help you avoid heavy lifting and bad working environment. We are of course available if you still have questions about the products or anything else. On the “Contact” page you can find our contact form and phone number. Otherwise you are welcome to contact us by e-mail sales@dancables.dk.